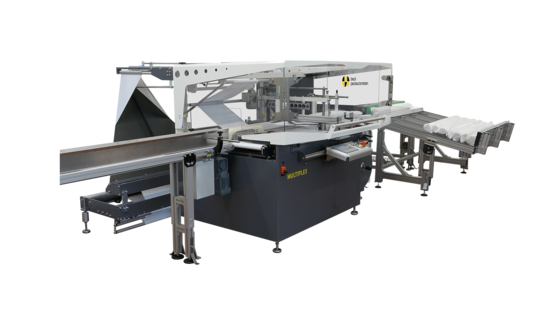

beck-paperbag Multiplex

Paper packaging with form shoulder principle sets new standards

This innovative packaging machine processes heat-sealable, recyclable paper (95/5) and produces tight, attractive packaging with attractive, stable 3-sided sealing seams.

The packaging machine impresses with its great flexibility, high degree of ease of operation and maintenance, and very compact design.

Details

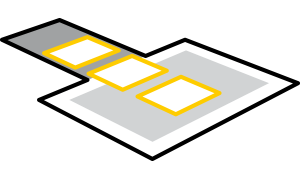

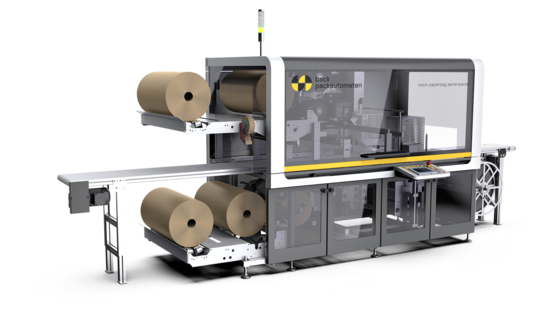

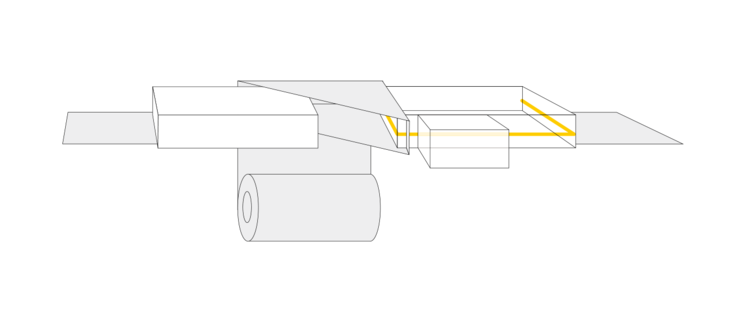

Forming a paper tube using the forming shoulder principle

Optimized and user-friendly accessibility

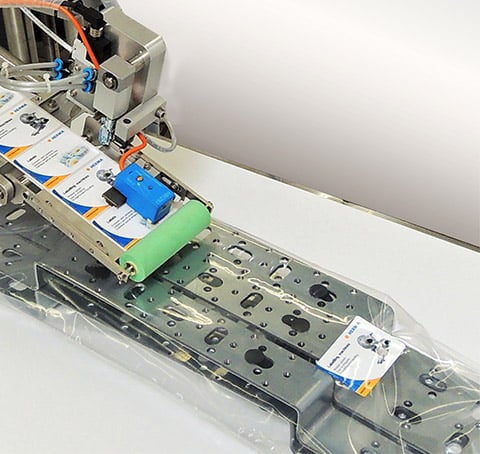

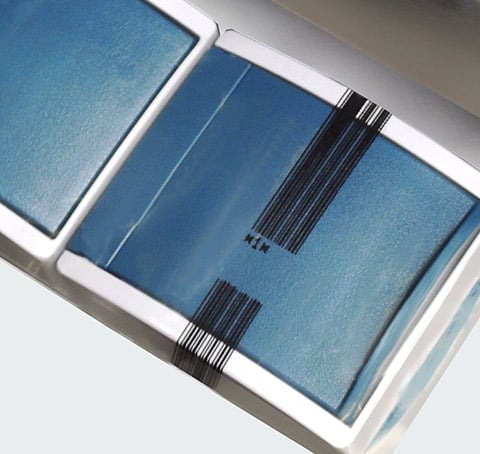

Printing on the paper bag

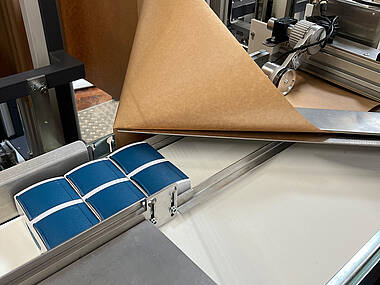

Packaging of sockets on beck-paperbag Multiplex

All videos ›As an innovative alternative to film packaging, the beck-paperbag Multiplex with form shoulder principle has now also been developed for paper. For flexible packaging of a wide variety of products in all industries.

Both unbleached and bleached paper can be used, either printed or unprinted. No additional consumables such as adhesive or sewing thread are required. The packaging material used can be disposed of with waste paper and thus returned to the material cycle.

The machine concept enables paper packaging of a wide variety of products in an automatic packaging process. This produces attractive packaging with stable sealing seams. In addition, a wide range of products can be processed thanks to the full-surface transport through the machine. It also offers the advantage of simple and flexible format changes without long setup times.

A wide variety of labeling systems, such as inkjet, thermal transfer, labeling, or print mark control, can be used to display product information on the paper bag. This ensures that the product remains visible to the customer.

Overview of advantages:

- Paper packaging for a wide variety of products in a single process

- Three-sided paper packaging with proven form shoulder principle and stable sealing seams

- Easy integration of marking systems that enable visual presentation of product contents

- Can be used with a wide range of papers

- Compact and space-saving design

- Machine concept for excellent accessibility, operation, and maintenance

- Simple and flexible format changes, short setup times

- Ergonomic material changeover – even with large paper rolls

Can be equipped with a variety of options:

- Integration of marking, and labeling systems

- Integration of feed and removal lines

50 - 400 mm*

150 mm*

30 cycles/min*

*depending on product, feed, paper and labelling

Beck form shoulder machines – versatility and flexibility in formats and materials.

The wide range of form shoulder machines from beck packautomaten sets standards, now also in paper. The form shoulder principle achieves exemplary flexibility with different formats and materials. A roll of paper is guided over a form shoulder and then sealed on three sides.

Suitable packaging Solutions

Additional Machines

Other industries

Film packaging for a variety of printing & paper products

Read morePackaging for a variety of textile products

Read moreFilm packaging for a variety of food, drink & tobacco products

Read morePackaging for a variety of household & leisure products

Read moreFilm packaging for a variety of plastic & rubber products

Read morePackaging for a variety of technical products

Read morePackaging for a variety of contract packaging products

Read morePackaging for a variety of healthcare products

Read morePackaging for a variety of wood products

Read morePaper packaging for e-commerce and mail-order business

Read moreForm, fill and seal machines from beck packautomaten: Versatility and flexibility

beck packautomaten offers you a wide range of form, fill and seal machines using which you can package your products with high quality and securely. These packaging machines are distinguished by impressive versatility and flexibility. Format and material changes are easy with form, fill and seal machines, and many different packaging solutions for many different products can be realised.

For the form shoulder principle, the packaging material is first fed over the forming shoulder and formed into a packaging that is then filled with the product and sealed on three sides or overlapping. Thereby the product can be fed both manually as well as automatically – completely as you require.

Your advantages of beck form, fill and seal machines at a glance

Form, fill and seal machine from beck packautomaten are distinguished by highest quality and efficiency.

Here are some further advantages at a glance:

- › Maximum flexibility of formats and materials

- › Many optional functions for individual solutions

- › Models with product data memory for more efficient processes and easier format changes

- › Long service life and low wear of the sealing systems

- › Space saving design and easy operation

You obtain form, fill and seal machines from beck packautomaten that meet your requirements and positively influence your packaging processes. We are also happy to develop integrated solutions for you for holistic, automated production processes.

Individual packaging solutions with form, fill and seal machines

beck form, fill and seal machines are available in various working widths and for different performance requirements. We provide the complete range, from a special design for limited space conditions to starter models to form, fill and seal machines for the packaging of large-volume products, from which we can develop an appropriate individual solution for you.

In doing so, many different packaging options can be implemented. Everything is possible, from the simple sealing on three sides to the sealing of a Euro slot to carrying handle packaging. beck packautomaten also provides the appropriate solution for labelling, printing or marking of your packaging. Easy to use tear-open strips or perforations and practical set packaging can also be implemented with beck form, fill and seal machines.

We use the decades of experience that we were able to acquire from the collaboration with companies from many different industries to design even better individual packaging solutions for you. See the versatile possibilities for yourself that our form, fill and seal machines provide for you. We look forward to your enquiry.