beck-Schrumpftunnel HV 1002 HPLS

Unique for demanding packaging

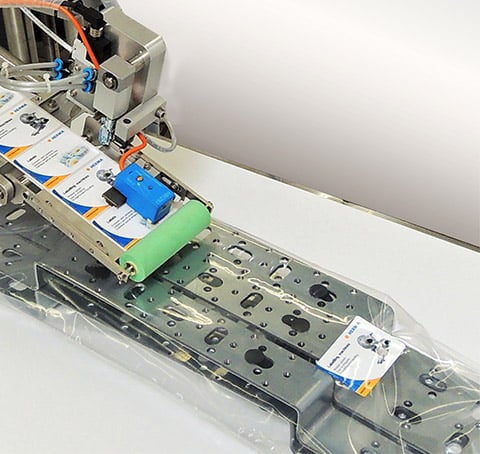

The HV 1002 HPLS is ideally suited for particularly large-volume or very wide products up to 1,000 mm and shrinks them effortlessly and efficiently. It harmonizes perfectly with our beck- Serienpacker SX.

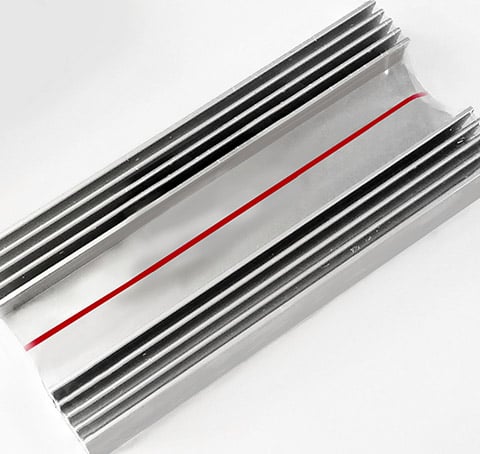

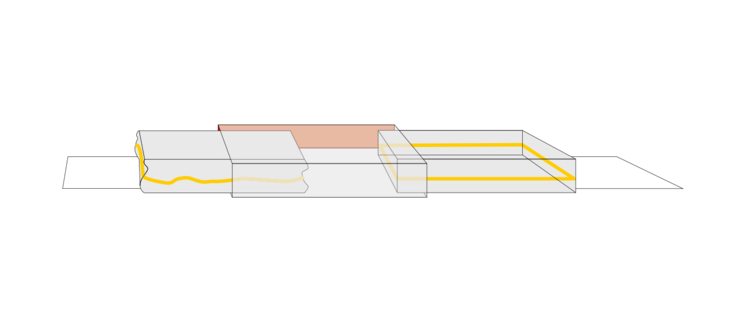

Packaging of insulation plates on beck-Serienpacker SX and beck-Shrink tunnel HV 1002 HPLS

All videos ›Advantages at a glance:

- By replacing your old shrink tunnel with a new beck-shrink tunnel, you reduce your electricity consumption and save up to 45 % energy depending on the film types and thicknesses used.

- The thermal insulation concept minimizes thermal outflow and an efficient heating and air guiding concept for precise adjustable air guiding and volume flow.

- The beck-shrink tunnel is built solid and sustainably. By using long living components and the reduced space requirement, you ensure space for further logistics processes.

Can be equipped with a variety of options:

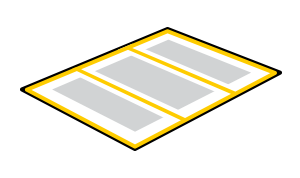

- Chain link conveyor

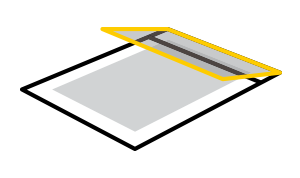

- Increased passage height

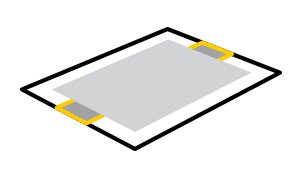

- Rotating tunnel bars: one sided adjustable or two sided fixed

- Different distances between tunnel bars

- Tunnel with separate touch screen

- Transfer rollers before and/or after the tunnel

- Cooling fan

- Blowing device and pressure rollers

- After running transport in case of power failure

- Cooled guiders leading through the shrink tunnel

- Product tracking (FiFo)

1000 mm*

180 / 310 mm*

120 / 250 mm*

*depending on products, feeding, labelling and film

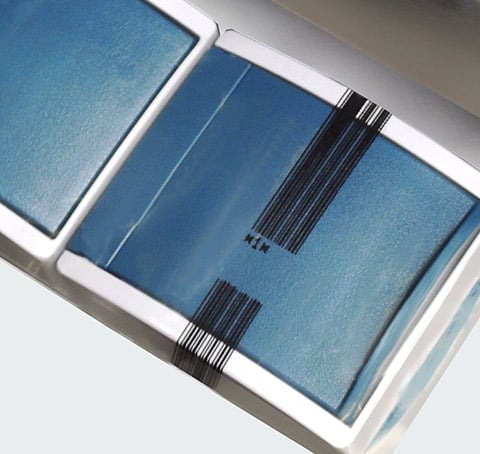

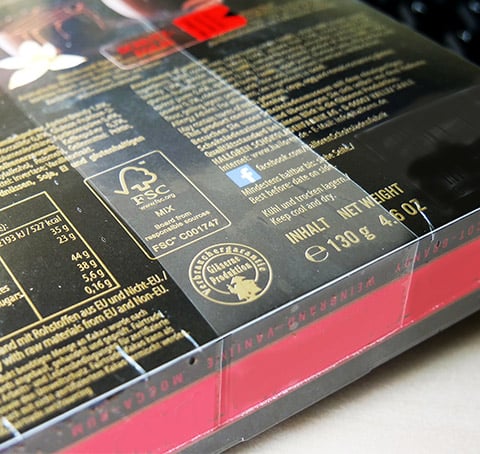

beck-shrink tunnels: brilliant results with different types of film.

beck-shrink tunnels ensure brilliant and perfect shrinking results. The heart of this is a special control system in connection with fast-reacting heating elements. For the shrinking, heated air is led around the product, wrapped in film, with special air flows. The special air guiding technology is the basic for special energy efficiency. The new beck shrink tunnel HV 602 is available in several sizes and performance ranges as well as with different transport systems such as tunnel bars or a chain link conveyor.

Product samples

Suitable packaging Solutions

Additional Machines

Other industries

Film packaging for a variety of printing & paper products

Read morePackaging for a variety of textile products

Read moreFilm packaging for e-commerce and mail-order business

Read moreFilm packaging for a variety of food, drink & tobacco products

Read morePackaging for a variety of household & leisure products

Read moreFilm packaging for a variety of plastic & rubber products

Read morePackaging for a variety of technical products

Read morePackaging for a variety of contract packaging products

Read morePackaging for a variety of healthcare products

Read morePackaging for a variety of wood products

Read moreBigger performance lower consumption The new beck- shrink tunnel HV 602 a bundle of energy in the matter of sustainability.

The HV 602 achieves brilliant and perfect shrinking results with up to 45% energy savings. It achieves truly high performance and meets every demanding requirement for film shrinking, products, energy efficiency and cost effectiveness.

Whether in the packaging of printing and paper products, textiles, plastic and rubber products, technical products, food and beverages, wood products, household and leisure goods or medical products. With the new shrink tunnel, a much better shrink result can be achieved with much lower temperatures than before. Due to a special air-guiding technology, the use of more powerful systems is no longer necessary.

Thus, the necessary energy for optimal shrinkage is greatly reduced. The new concept ensures lower temperatures at the tunnel surface, which also contributes to energy savings.

Another highlight is the reduction of space requirements by 30%. The integration of the control cabinet into the machine frame and the shortened infeed and outfeed conveyor at the same hood length ensure space for further logistics processes.

The new beck-shrink tunnel HV 602 is available in several sizes and performance ranges as well as with different transport systems such as tunnel bars or a chain link conveyor. All in accordance with individual customer wishes and requirements.

It is easily controlled via a modern touchscreen on the upstream placed packaging machine. Optionally, an operator panel is available, which is attached directly to the shrink tunnel. This means a mobile use in the packaging processes on site.

beck packautomaten has always been known for high-quality machine concepts. When redesigning the shrink tunnel, great attention was therefore paid to the longevity of the parts and materials used and the interaction between them. The result is less wear on the components. This makes the tunnel even more sustainable and increases the useful life of the parts.